design and manufacturing of stamping tools

We have more than 20 years of experience in designing and manufacturing stamping tools!

Our company is undertaking the design and production of stamping tools, supported by an efficient product management, own material stock, up-to-date machines and a 90 strong expert team. The test-pressing, qualification and delivery belong to our services too.

If you are looking for a turnkey solution to produce stamping tools we are help to assist you! Do not hezitate to contact us!

OUR PROCESSES

Project management

Our multilingual project management team is in daily contact with our customers, takes care of the follow-up and coordination of projects.

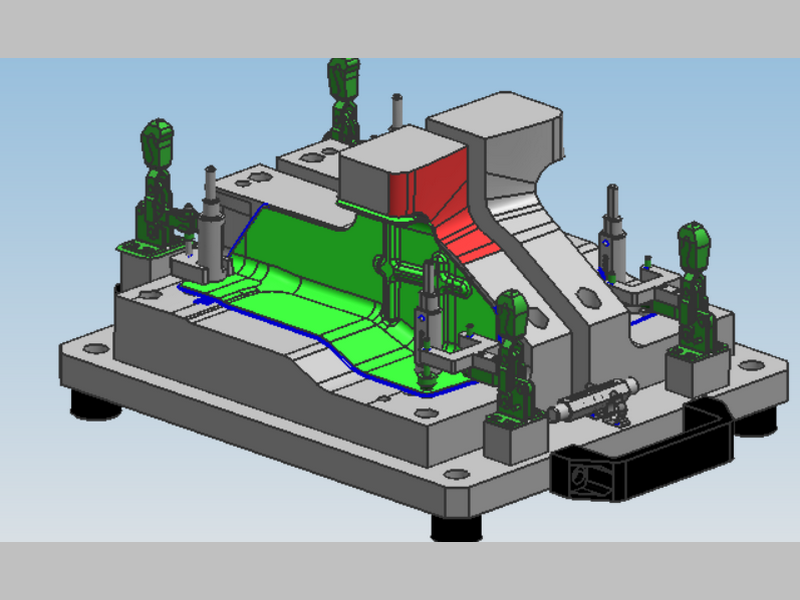

Tool design and simulation

There are 10 full time tool designers working at our company. We use CAD/CAM software (NX8,5 and AUTOCAD) for designing. In case of the geometrical shape of the part our colleagues can prepare a simulation analysis even in the quote phase on the feasibility options of the part. We use the AUTOFORM R6 software for simulation.

Production management system

Our company is using a product management system software, called QAID for the follow up of products, which is a software uniquely designed for manufacturing companies. This system follows-up all items starting from the initial enquiry up to the recalculation of the readymade product.

Own materials on stock

To fulfil our customers’ requirements and to achieve a possible short lead time, we hold reasonable consignment material stocks at our site, thus, to avoid waiting times for material deliveries from third parties in urgent cases.

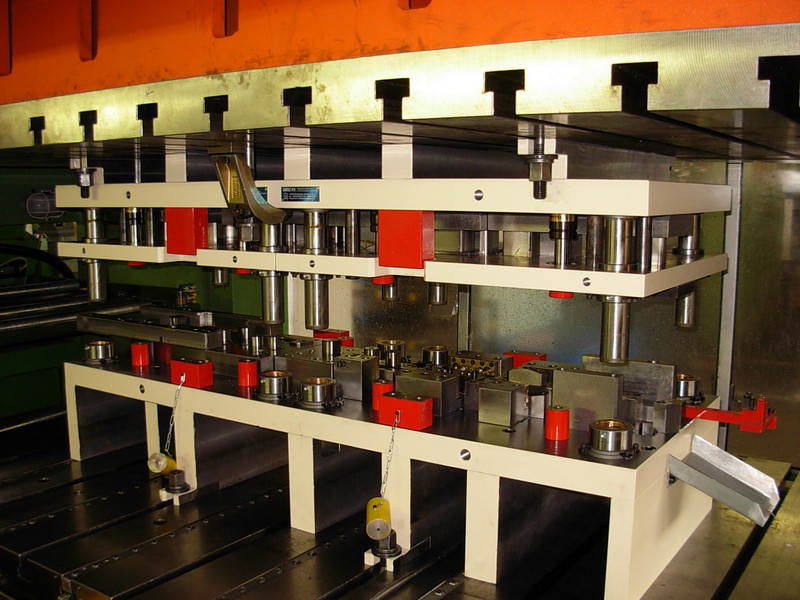

Modern CNC machines

The necessary programs for the shaping works are done with a modern 3D CAD/CAM software (PowerMill 13,1). Our factory has 11 pcs of CNC DECKEL and HURCO machines, out of which one machine a portal milling machine and 3 of them are 5 axis shaping machines. Beside this we have 5 pieces of MISUBUSHI wire extruder machines.

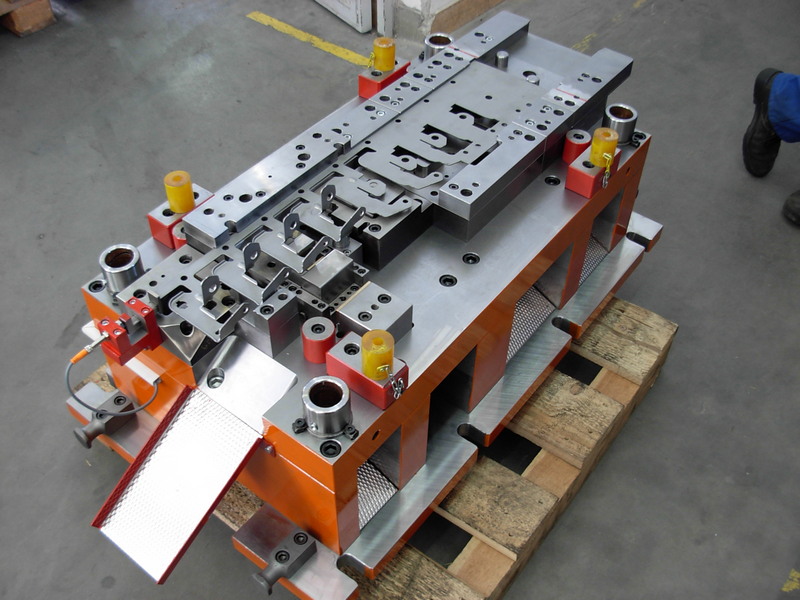

Toolmaking & Assembly

Our experienced toolmaking staff responsible for the assembly of the manufacturing products designed and produced by us. We have a staff of 14 people working as tool-makers, in 2 shifts. We have all the necessary, good quality tools for creating high quality and precise tools for our customers. Due to our technical conditions, we are able to fit parts together up to 10 tons gross.

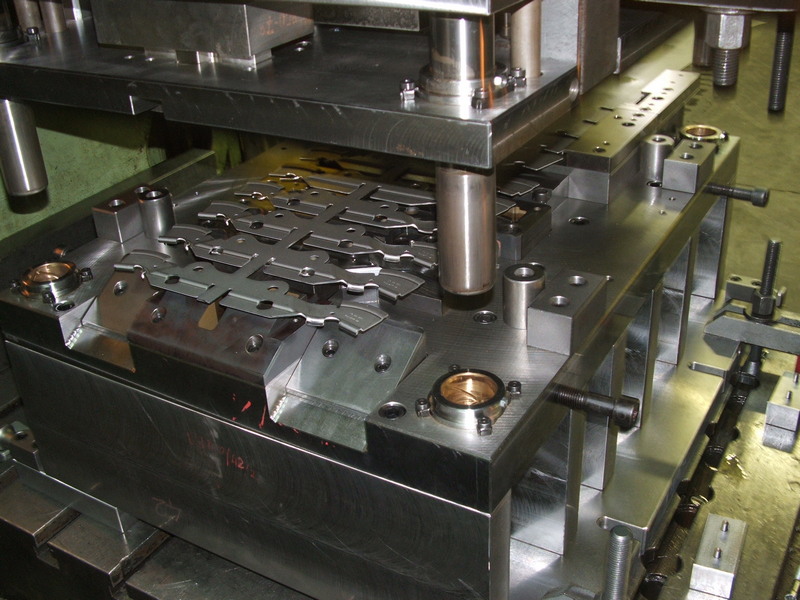

Tool tryout

Until handing over products, designed by our company, the first tests of tools and the optimization of tool try-outs are done with 500 tons eccentric press machine.

Quality assurance

Delivery /HLTO support

We can deliver our products to your company premises up to 6 tons with our own trucks.

Our clients