LASer cutting

Laser cutting – the most modern plate cutting technology of the 21st century!

… which results in accurate measurements. Our company also undertakes flat plate cutting, thick plate cutting, simultaneous 5-axis laser cutting of formed plates and welding (also simultaneously in 5 axes). Laser cutting is an affordable and fast technology that meets even the most stringent requirements. Request a quote!

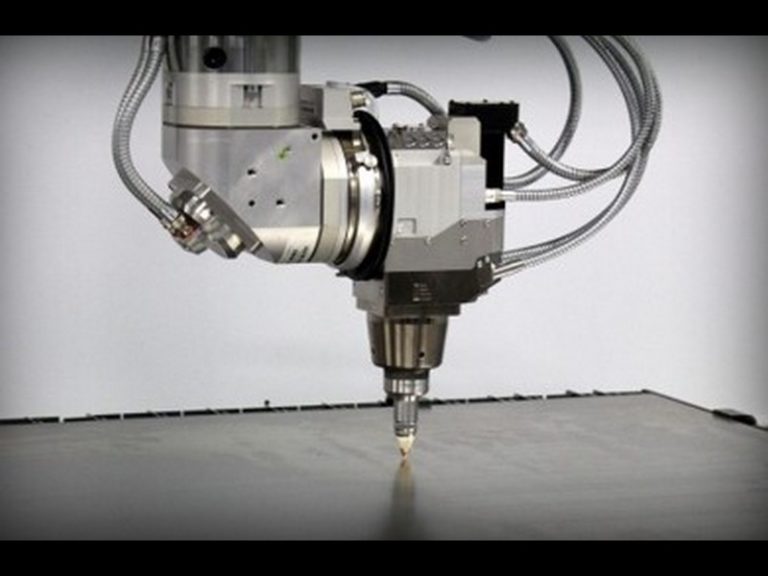

TRUMPF TRU LASER CELL 7020 FIBER

The TruLaser Cell Series 7000 can be used for cutting, welding and deposition welding. For cutting applications, the laser beam is coupled into the fiber core, while in welding applications it is coupled into the outer ring. In each case the appropriate depth of field and the optimum beam focal diameter are guaranteed.

The TRUMPF TruLaser Cell Series 7000 sets new standards in terms of speed and production efficiency. A major contributing factor is unrivaled positioning speeds and axis acceleration rates.

On-the-fly piercing when cutting with the FastLine Cell reduces unproductive time by up to 40%. The dynamic cutting optics allow very high acceleration rates and ensure a constant distance between the nozzle and the workpiece. The LensLine function monitors the focusing lens and disconnects the laser before it emits any contaminating vapor, preventing contamination of the beam guidance system and increasing availability.

We undertake:

- Flat plate cutting/flat pattern cutting

- Thick plate cutting by simultaneous

- 5-axis laser cutting of formed plates

- Deposition welding, also simultaneously in 5-axis

PARAMETERS:

- Working range: 2000x1500x650 mm

- 2D flat resp. 3D shaping

- Workable materials:

- Aluminum up to 4 mm thickness

- Stainless steel up to 4 mm thickness

- Steel up to 8 mm

- Coated plates/sheets

- SAT

- STL

- DXF

- CATIA 4.2 (mod)

- CATIA 4.2 (exp)

- STEP

Our clients