our services

Design and manufacturing of stamping tools

Our company is undertaking the design and manufacturing of stamping tools, supported by an efficient production management process, own material stock, modern manufacturing machines and a strong expert-team of 90 people. We provide test-pressing, qualifying and delivery services too. Are you looking for a turnkey solution for manufacturing stamping tools? You have found it!

Design and production of injection-moulding tool

We are undertaking the design and production of injection-moulding tools. During the production process we are taking the type and characteristics of the plastic materials to be used into consideration, along with the planned life span and required quantity of the manufactured parts too. Our designer colleagues will design the injection-molding tools in collation and consultation with you.

Automatic production cell

In our automatic cells we also take on the production of active parts of tools with its finishing smoothing operations and the cutting of electrodes with zero-point system. The milling, and wire EDM will be at micron accuracy and up to 5 pallets can be pre-programmed. We implement automatic production in our robotic-controlled, closed production-cell. The milling is done by our HSC-type machine up to 62 HRC temper.

Laser cutting

We undertake sheet-cutting, thick-plate cutting, cutting of formed plates; we also do simultaneously 5 axis lasers cutting and normal welding too. Working range: 2000 x1500x650 mm, 2D flat surface respectively 3D works up to 4 mm thickness), steel (up to 8 mm thickness) and coated plates. Have an upcoming project?

Laser welding

In recent times laser welding is considered as a widely used process in several industrial areas where accuracy and high productivity is required. The laser welding process using no added materials, because of this it’s surpasses the traditional welding methods by its rapidity, thin joints, and strength. Looking for a laser welding partner?

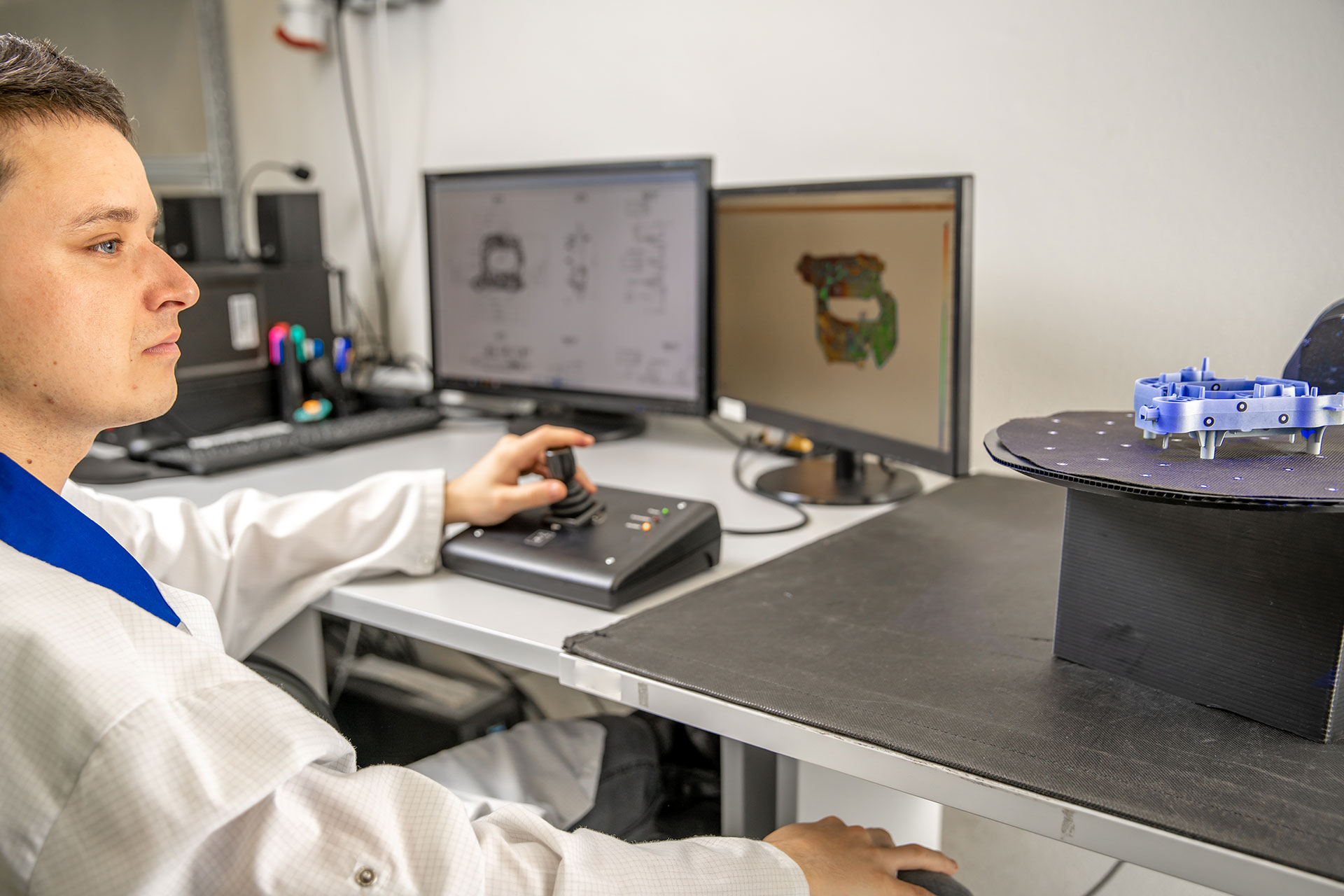

Megvalósíthatósági tanulmányok & Bérmérés

During the reverse engineering modeling process after digitalizing the already existing parts we prepare a CAD model using the dot-map of the processed parts. The reverse engineering can be used in cases of re-designing or re-production of parts where there is no documentation available.

OUR PROCESSES

Project management

Our multilingual project management team is in daily contact with our customers, takes care of the follow-up and coordination of projects.

Tool design

We work with 10 in-house professional tool designers.There are 10 full-time in-house tool designers working at our company. We use CAD/CAM software (NX8,5 and AUTOCAD) for designing.

Purchasing

Our purchasing team is responsible for providing a reasonable consignment material stocks at our site to avoid waiting times for material deliveries from third parties in urgent cases.

Tool manufacturing

We undertake the manufacturing of stamping and injection molding tools along with measurement tools.

Tool assembly

The qualification of the parts produced by our tools are done on our WENZEL type 3D CMM measuring device. This process is supported by a NIKON 3D scanner and a profile projector as well.

Tool tryout

Until handing over products, designed by our company, the first tests of tools and the optimization of tool try-outs are done with 500 tons eccentric press machine.

Quality Assurance

The qualification of the parts produced by our tools are done on our WENZEL type 3D CMM measuring device. This process is supported by a NIKON 3D scanner and a profile projector as well.

HLTO support

We can deliver our products to your company premises up to 6 tons with our own trucks.

Our clients